Technology

Advanced Production Equipment

The company possesses multiple composite material molding production lines and advanced equipment

• Two 3500-ton SMC molding machines (one manufactured with German technology, working area 4.7m*4.2m) and one 1200t SMC molding machine (working area 3.2m*2.8m), capable of meeting the manufacturing needs of various sizes of products

• Equipped with various new RTM injection, VI vacuum guiding, and other molding process equipment; possesses world-class molding technology and multiple production lines to meet the mass production needs of customers

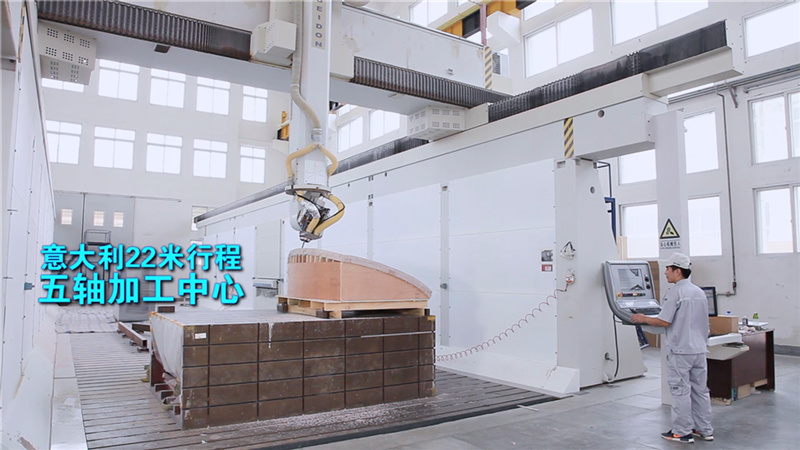

• Italian imported five-axis linkage machining center, capable of independently producing large-scale tooling molds such as head covers, meeting various personalized design requirements

Advanced Technological Capabilities

The company maintains long-term cooperation with French company Compiegne and Japanese company Yakisuru, introducing and absorbing world-class technologies, and exploring and developing various new composite materials and process technologies

• Passenger compartment seating - RTM+ production technology from STRATIME, France

• Vehicle body head cover, console, and driver's cab interior production technology from DEFI 22 COMPOSITE, France

• High-end double-sided polished fiberglass paste and mold making technology from Yakisuru Co., Ltd., Japan, as well as bathroom module and passenger compartment interior production technology